In the energy storage industry, the terms "Storage EMS" and "SCADA" are sometimes used interchangeably; but they refer to very different systems with very different capabilities. Understanding the distinction is essential for anyone deploying or operating battery energy storage systems.

What Is SCADA?

SCADA (Supervisory Control and Data Acquisition) is a system architecture for monitoring and basic control of industrial processes. In energy storage, a SCADA system collects data from batteries, inverters, meters, and other equipment, displays it on operator dashboards, and provides manual or rule-based control commands.

SCADA has been the standard for power generation monitoring for decades. It excels at data collection, alarming, and providing operators with real-time visibility into system status.

What Is a Storage EMS?

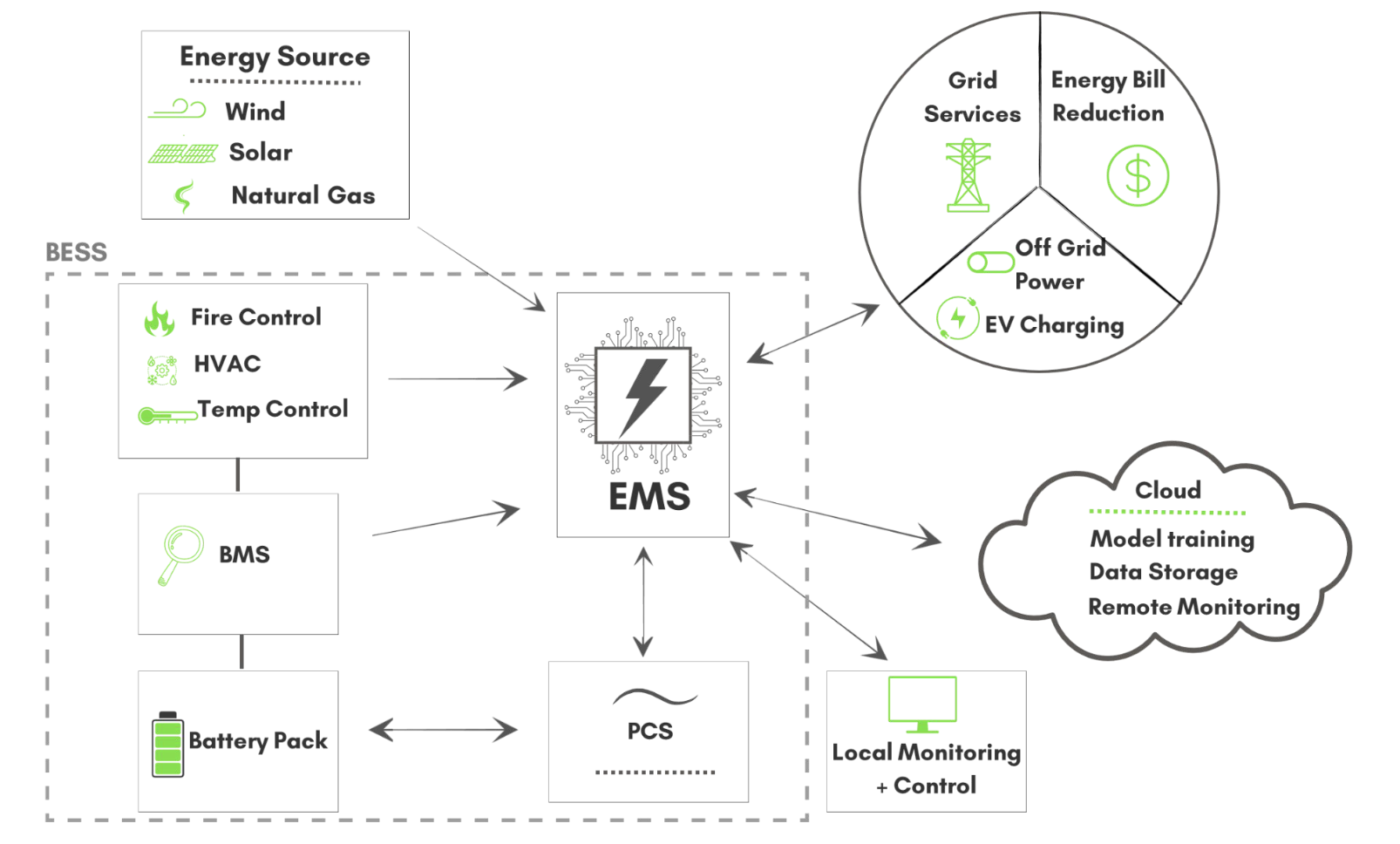

A storage EMS (Energy Management System) goes beyond monitoring to actively optimize battery dispatch in real-time. While SCADA shows you what is happening, a storage EMS decides what should happen; and makes it happen automatically.

A storage EMS processes data from the same sources as SCADA (meters, inverters, BMS, weather) but adds economic optimization algorithms that determine the best charge/discharge strategy at any given moment.

Key Differences

Passive vs. Active Control

SCADA is primarily a passive system. It monitors, records, and alerts; but dispatch decisions are either manual or based on simple rules (e.g., "charge when price is below X, discharge when above Y"). A storage EMS uses sophisticated optimization algorithms that consider dozens of variables simultaneously to make dispatch decisions that maximize revenue.

Data Collection vs. Economic Optimization

SCADA collects operational data and presents it to operators. A storage EMS uses that same data; plus market signals, weather forecasts, load predictions, and tariff structures; to solve complex optimization problems in real-time.

Rule-Based vs. AI-Driven

Traditional SCADA uses fixed rules or operator commands. A storage EMS employs machine learning and predictive algorithms that adapt to changing conditions, learn from historical patterns, and improve performance over time.

Single-Asset vs. Portfolio Management

SCADA typically monitors one site at a time. Modern storage EMS platforms provide fleet-level management, allowing operators to compare performance across sites, allocate resources optimally, and manage an entire portfolio from a single interface.

Do You Need Both?

In most modern deployments, a comprehensive storage EMS includes SCADA-level monitoring capabilities. The EMS collects all the same data points, provides dashboards and alarms, and adds the optimization layer on top. You get monitoring and control in a single platform.

Some projects; particularly those with complex utility interconnection requirements; may still require a separate SCADA system for regulatory compliance. In these cases, the storage EMS integrates with the SCADA system and handles the economic optimization while SCADA handles the utility interface.

The Revenue Impact

The difference is measurable. Projects running with SCADA-only control typically capture 60-75% of available revenue. Projects with a well-optimized storage EMS capture 90-95% or more. Over a 15-year project life, that 20-30% gap represents a significant impact on returns.

WATTMORE's Intellect Operate combines full SCADA-grade monitoring with AI-powered dispatch optimization. Learn how Intellect Operate can maximize your storage asset's value.